Flow Rate

Revision | Date | Description |

|---|---|---|

| 17.02.2025 | Init document |

Introduction

Calibrating the Flow Rate (Extrusion Multiplier) is a crucial step in improving print quality, especially if you're experiencing issues with under- or over-extrusion.

Requirements

Test Print

The best way to calibrate is by printing a thin-walled object:

Prepare a 20x20x20 mm cube model in Orca Slicer:

Top Layers = 0

Bottom Layers = 1-2 (to ensure adhesion)

Infill = 0%

Perimeters = 1

Line Width = 0.42 mm (do not change it to 0.4 mm!)

Flow Rate = 100% (as a starting point)

Print and measure the wall thickness using calipers.

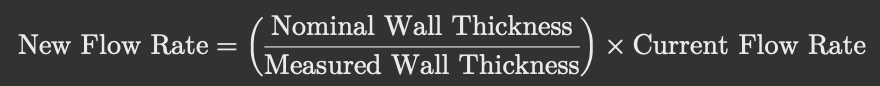

If the measured thickness differs from 0.42 mm, calculate a new Flow Rate value.

Flow Rate Adjustment Based on Line Width

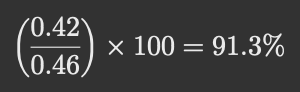

Too Much Filament

Set Line Width: 0.42 mm

Measured wall thickness: 0.46 mm

Flow Rate set to 100%

→ New Flow Rate: 91%

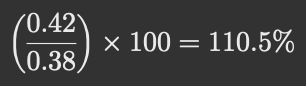

Too Little Filament

Set Line Width: 0.42 mm

Measured wall thickness: 0.38 mm

Flow Rate set to 100%

→ New Flow Rate: 111%

Applying the Adjustment in Orca Slicer

Orca Slicer → Filament Settings → Flow Rate (Extrusion Multiplier)

Enter the new value.

Reprint the test model.